Chemical Rust Treatment Comparisons

back to Solo Hobbit's VW bus home page

There is anout 1.2 MB of information on this page.

Those with slower connections will have to be patient.

There is some stuff to read before getting to the results pictures anyway.

This page compares chemicals commonly available in the United States which are intended to treat rust corrosion on steel. It is primarily directed toward the use of such treatments on automobile sheet metal and specifically split screen vintage (1967 and earlier) Volkswagen busses, since that is my hobby which lead me to do this comparison.

Page Contents

Corrosion of Iron (electrochemical

cell, cathode, anode, electrolyte, road salt)

Excluded Treatments (POR-15,

Corroless, Enrust, H402, Miracle Rust Remover and Metal Prep, OxiSolv, Rass-O-Nil, Ospho,

Neutra-rust )

Types of Treatments (these are color coded

throughout this page):

Testing Method

Comparison Results and Organization

My Conclusions

VW bus sheet steel is formed primarily of iron. The corrosion of iron is a complex electrochemical reaction in which the iron combines with both oxygen and water to form iron oxides such as magnetite Fe3O4 (black rust) and ferric oxide Fe2O3 (brown or red rust) among others. The reaction occurs when there is a difference in the electromotive potential of metals in the presence of a conductor. This creates a electrochemical cell which has the following parts:

cathode: the more noble metal (less reactive on the electromotive series)

anode: the less noble metal (more reactive on the electromotive series)

electrolyte: conductor such as water which in the case of iron corrosion also provides oxygen

Electrons flow from the anodic area to the cathodic area causing the metal to corrode by forming soluble positive ions at the anode. The overall reaction for the formation of ferric oxide:

® 2Fe2O34Fe + 3O2

may be written as two separate equations:

® 4Fe3+ + 12e- and 3O2 + 12e- ® 6O2-4Fe

The iron loses electrons (e-), so it is said to be oxidized. The oxygen gains an equal number of electrons and it is said to be reduced. For more information on the process of iron corrosion see: http://naio.kcc.hawaii.edu/chemistry/everyday_corrosion.html, and for a chart of the electromotive series of metal see: http://www.britannica.com/bcom/eb/article/single_image/0,5716,304,00.html or http://www.mtgloans.com/~thelen/1galv.html

Such an electrochemical cell can form between different metals, between different pieces of the same metal, and even within the same piece of metal for the following reasons:

Sheet metal is rarely pure and almost certainly contains more noble metals.

Electrochemical cells may also form on a chemically homogeneous metal in areas of mechanical stress, such as a dent or a bend, and concentrate the corrosion along this stress line. Sheet metal will corrode preferentially at the point of the bend.

Even if a metal is pure without area of stress, the presence of rain water mixed with dirt and grime (which contains traces of salts of nobler metals) can cause the formation of local electrochemical cells at the metal surface.

This last point is also closely related to destructive nature of road salt. Road salt mixed with water will accelerate the formation of rust by increasing the conductivity of the electrolyte in the cell and specifically as follows:

At the surface of the more noble metal (the cathode) negatively charged hydroxide ions are formed:

2H2O + 2e ® H2 + 2(OH)-

These hydroxides combine with sodium ions from the salt water to form sodium hydroxide:

Na+ + OH- ® NaOH

At the surface of the less noble metal (the anode) positively charged ferrous ions are formed:

Fe+ - 2e ® F+2

These ferrous ions combine with chloride from the salt water to form ferrous chloride:

Fe+2 + 2CI- ® FeCl2

The sodium hydroxide and ferrous chloride yield ferrous hydroxide where they meet:

FeCl2 + 2NaOH ® Fe(OH)2 + 2NaCl

In the presence of oxygen, a secondary reaction further oxidizes the ferrous hydroxide to form hydrated ferric hydroxide (red-brown rust):

4Fe(OH)2 + O2 ® 2H2O + 2Fe2O3 × H2O

If oxygen is limited, this secondary reaction is modified to form hydrated or black magnetite:

Fe3O4 × H2O ® H2O + Fe3O4

Of course, the subject of electrochemical corrosion of iron is vast, and this has just highlighted the subject. Some of the information here comes from Basic Methods of Conserving Underwater Archaeological Material Culture by Donny L. Hamilton, Nautical Archaeology Program, Department of Anthropology, Texas A&M University, Spring 1997.

Paints and coatings which are intended to be applied over a rusted surface to encapsulate the rust but not chemically change the rust, are not included in this comparison. Some of these products are:

POR-15; Resto Motive Laboratories, Inc.; PO Box 1235, Morristown NJ 07962, phone: 800-457-6715 http://www.por15.com

Corroless; Eastwood; phone: 800-820-9042 http://www.eastwoodcompany.com

Zero Rust; www.zerorust.com

Enrust; P.O. Box 1165 / 800 S. Acadia Road, Thibodaux, LA 70301; Phone: 504-449-0730 or 800-325-3407; Fax: 1-504-449-0740; email: Customer Service@NAPASCO.com; web: http://www.napasco.com/enrustreat.htm

In addition, the following products were not included due to lack of time and money:

H402 Sodium Metasillicate pentahydrate and IGAPAL mixed with the baddest solvent around. Mike West mwest@cdsnet.net Said to desolve steel

Miracle Rust Remover and Metal Prep; Bill Hirsch Automotive; phone: 800-828-2061; $14.00 / 20oz; Manufacturer's Description: Removes rust and leaves gray phosphate coating on the metal to provide an excellent base for painting and welding conductivity.

OxiSolv; Eastwood; phone: 800-820-9042; $10.00 / 16oz; Manufacturer's Description: Dissolves iron oxide rust completely leaving a gray, zinc phosphate coating. Non-toxic!

Rass-O-Nil; web: http://www.icpi.net/rassonil.htm a phosphoric acid solution with zinc

Ospho; Skybryte Co. 3125 Perkins Ave Cleveland, OH 44114; phone: 216 771-1590; supposedly available from True Value hardware stores

Neutra-rust (no information)

| Electrolysis basically

reverses the electrochemical reaction which created the rust in the first place. It

does not restore the oxidized iron to its original state, but rather removes the rust from

the surface of the unrusted metal below. The iron that rusted in the first place was

an anode in the electrochemical cell. Electrolysis reverses the reaction by making

the rusted object into the cathode and some other piece of metal into the anode. An

electromotive difference is created between the cathode and anode with the use of a direct

electric currant. Just as in the original reaction which created the rust, the anode

and cathode must be bridged with an electrolyte. The anode is the positive terminal

of the electrolytic cell, to which electrons, negatively charged ions, travel when an

electric current is passed through the cell. Oxidation occurs at the anode and oxygen is

evolved. The cathode is the negative terminal of the electrolytic cell to which positively

charged metallic ions travel. At the cathode, reduction takes place and hydrogen is

evolved. For some good resources on how to do electrolysis, see http://www.bhi.co.uk/hints/rust.htm by Ted

Kinsey or http://www.oldengine.org/members/billd/electrol.htm.

Full immersion is required and rust is more effectively removed from the cathode

when the surface is in a direct "line of sight" with the anode.

|

Friendly Acids

are ones which are not as caustic as the others in this comparison. Full immersion

works best for these products:

|

Plain Phosphoric Acid Based rust treatments are used for two main reasons:

The phosphate in the acid converts ferric oxide (Fe2O3) into iron phosphate (FePO4) and water in a faster simple exchange reaction:

The water is removed when the part is cleaned but the iron phosphate will adhere due to surface effects so that it does not wash away. The hydrogen ions in the acid will attack the iron and convert it into iron phosphate (FePO4) and hydrogen gas (the bubbles) in a slower reduction-oxidation reaction:

Unless the metal is exposed to the acid for a extended period and in sufficient concentrations, the effect of the acid attacking the steel will be negligible. Some of the above information comes from Lee M. Daniels, Laboratory for Molecular Structure and Bonding, Texas A&M, daniels@tamu.edu [email updated July, 2001] Since phosphoric acid works well for rust treatment, there are numerous products in this category:

|

| Phosphoric Acid with Zinc works

like plain phosphoric acid with the addition of leaving a zinc residue on the treated

surface. The zinc is intended to protect the metal from further corrosion in the

same way galvanizing protects steel through passive cathodic protection. The iron

originally rusted since it was the anode (or more reactive) in an electrochemical cell.

Cathodic protection introduces a metal more reactive than iron (in this case zinc)

into the cell. Thus the iron becomes the cathode and the zinc becomes the

anode. The result is that the zinc will now be more prone to oxidation and corrosion

and the iron will be protected. If the conditions are right, the zinc will

eventually be consumed. However, zinc is consumed slower than iron. This is

true, even though zinc is less noble and more reactive than iron. Zinc oxide

created in the corrosion process, forms a protective barrier on the surface which prevents

further corrosion. Iron oxide formed when iron corrodes, does not form such a

protective barrier, but rather the familiar flaky and brittle rust. Products

compared in this category include: |

Other Acids (besides phosphoric

acid) can be used in rust treatments including hydoxyacetic acid, sulfamic acid, and

hydrogen chloride. Hydrogen chloride (hydrochloric or muriatic acid) gives the same

two reactions as phosphoric acid with Cl in place of PO4, but in this case both

of the reactions are relatively fast, so the actual metal is lost at a rate similar

to the rust. Also, the FeCl3 produced does not adhere to the metal

surface as well, so you get little protection of the treated metal surface. Products

compared in this category include:

|

| Conversion Coatings are

applied over the surface of rust and, unlike the other treatments in this comparison, are

left in place. These products claim to covert the underlying rust to an inert

substance and leave a black primer for further coatings. I have found little

chemistry to explain these products: |

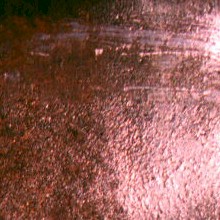

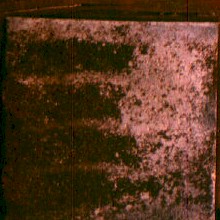

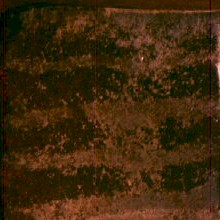

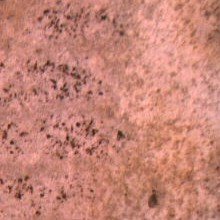

One half of a rusted steel bar was wire brushed (with an power angle grinder) and cut into squares to produce pieces which looked like this:

This was done to compare each treatment's effect upon both "raw" rust and rust which was has been wire brushed.

Typical Testing

Other than conversion coatings, each piece was full immersed for about 30

minutes. Results were then photographed both dry and after wetting with water to

improve clarity. Each piece was then further immersed for about 2 hours and each

piece was brushed manually with a small wire brush. Results were then photographed

dry.

Conversion Coating Testing

For conversion coatings, two coats were applied. Half of the finished surface was

scrapped to reveal the condition of the rust below. This scrapping was done

perpendicular to the original division of "raw" and wire brushed rust, to reveal

the condition of the rust both in the "raw" and wire brushed areas.

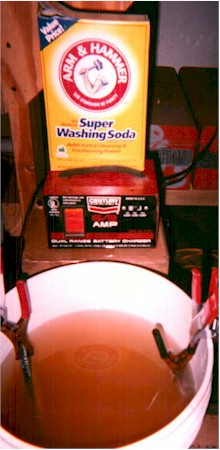

Click on this picture of

testing underway to view full size

Click on this picture of

testing underway to view full size

Click on this picture of

final results of all products to see full size.

Click on this picture of

final results of all products to see full size.

Comparison Results and Organization

A large table is used to organize information for each of the products compared. The products are listed across the columns of this table. The following information is listed down each of the rows:

Product Name

Manufacturer / Source

Cost

Cost per oz

Active Ingredients (CAS numbers are included for reference elsewhere)

Characteristics (pH and specific gravity)

Other Information (including manufacturer's description)

Product Name (repeated for reference)

Results after short treatment and no brushing- photographed dry

Results after short treatment and no brushing - photographed wet

Results after long treatment and brushing - photographed dry

Product Name (repeated for reference)

Untreated Comparison (right side was wire brushed before treatment; left side was left "raw")

My apologies, but the reader will need to do a bit of scrolling to see all the information.

| ELECTROLYSIS | "FRIENDLY" ACIDS | PLAIN PHOSPHORIC ACID BASED | PHOSPHORIC ACID WITH ZINC | OTHER ACIDS | CONVERSION COATINGS | |||||||||||

|

|

no picture (comes in bulk crystals) |

|

|

|

|

|

|

|

|

|

|

|

|

||

| Product Name | electrolysis | Ecotec | Simple Solutions Rust Remover | Rust-Mort | MP-7 | Naval Jelly | Dupont 5717S | Mirachem 250 | Dupont 5718S | Metal-Ready | Envirosolve 1000 | CLR - Calcium Lime & Rust Remover | Extend | One-Step | Rust-X | Product Name |

| Manufacturer / Source |

homemade | Singerman Laboratories 4091 Saltsburg Rd. Murrysville, PA 15668 phone: 800-798-7986 web: http://www.essex3 .com/slabs/metlmain.htm |

Simple Solutions R.R.5 Box 283G Gravois Mills, MO 65037 phone: 573-374-1746 fax: 573-374-4972 |

SEM Products, Inc. 651 Michael Wylie Dr. Charlotte, NC 28217 phone: 704-522-1006 |

Must for Rust Co. PO Box 972 Cedar Ridge, CA 95924 phone: 916-273-8283 |

Loctite Corp. (as Permatex) phone: 800-loctite |

Dupont, local distributors | Mirachem Corp. 1045 S. Edward Dr. PO Box 27608 Tempe AZ 85285 phone: 602-966-3030 fax: 602-966-0890 |

Dupont, local distributors | Resto Motive Laboratories, Inc. PO Box 1235 Morristown NJ 07962 phone: 800-457-6715 |

DHS Distributing Inc. 2602 Ryder Court League City TX 77573 phone: 713-334-3959 fax: 713-334-1069 |

Jelmar 6600 N. Linciln Ave. Lincolnwood, IL 60645 available at local hardware stores |

Loctite (as Permatex or Duro) phone 800-loctite |

Mar-Hyde Corp. 4677 Devitt Dr. Cincinnati OH 45246 phone: 513-874-5151 phone: 888-MA-HYDE |

Integrity Industries PO Box 5342 Kingsville, TX 78383 phone 512-595-5561 iii@trip.net |

Manufacturer / Source |

| Cost | very inexpensive | $11.00 / 32oz $25.00 / 128oz (gallon) $110.00 / 5gallon |

Company took my money, did not send product, and does not return calls. | $10.6 / 16oz | $6.00 / 24oz | $3.50 / 8oz jelly | unknown | $6.40 / 32oz | unknown | $13.00 / 20oz | $14.00 / 16oz | $5.25 / 28oz | $4.85 / 4oz liquid | unknown | unknown | Cost |

| Cost per oz | very inexpensive | $0.34375 /oz | $0.6625 /oz | $0.25 /oz | $0.4375 /oz | unknown | $0.2 /oz | unknown | $0.65 /oz | $0.875 /oz | $0.1875 / oz | $1.2125 /oz | unknown | unknown | Cost per oz | |

| Active Ingredients |

Negatively 12VDC charged rusted object submersed in a bath of 1 tabelspoon household lye (sodium hydroxide HNaO (CAS 1310-73-2)) or washing soda (sodium carbonate CNa2O3 (CAS 497-19-8)) per 1 gallon water with a positively 12VDC charged sacrificial iron electrode. | No ingredients listed on MSDS. Active

ingredients said to be: monosodium citrate C6H7NaO7 (CAS 18996-35-5); used elsewhere as buffer in solutions, emulsions, berverages and foodstuffs. [This information updated July 15, 2001] citric acid C6H8O7 (CAS 77-92-9) |

I assume citric acid based | 40-45% phosphoric

acid H3O4P (CAS 7664-38-2)

; used elsewhere in softdrinks, welding agents, semi conductors; pickling agents isopropanol C3H8O (CAS67-63-0) 1-5%; used elsewhere in solvent and deicing agent |

17.5% phosphoric

acid H3O4P (CAS 7664-38-2)

; used elsewhere in softdrinks, welding agents, semi conductors; pickling agents

|

25-30% phosphoric acid H3O4P

(CAS 7664-38-2) ; used elsewhere in

softdrinks, welding agents, semi conductors; pickling agents 1-3% sulfuric acid H2O4S (CAS 7664-93-9); used elsewhere in batteries, leather delimer, metal leacher 1-3% isopropyl alcohol (CAS 67-63-0) |

31% phosphoric acid H3O4P

(CAS 7664-38-2) ; used elsewhere in

softdrinks, welding agents, semi conductors; pickling agents 15% ethylene glycol monobutylether (CAS 111-76-2) |

phosphoric acid in undisclosed concentration; H3O4P (CAS 7664-38-2) ; used in softdrinks, welding agents, semi conductors; pickling agents | 7% phosphoric

acid H3O4P (CAS 7664-38-2)

; used elsewhere in softdrinks, welding agents, semi conductors; pickling agents 3% zinc oxide OZn (CAS 1314-13-2); used elsewhere in white pigment, photocopier sensitizer, drugs nickel phosphate H3O4P32Ni (CAS 10381-36-9); used elsewhere in yellow pigment |

phosphoric acid in

undisclosed concentration; H3O4P (CAS

7664-38-2); used elsewhere in softdrinks, welding agents, semi

conductors; pickling agents zinc phosphate in undisclosed concentration; O8P2Zn3 (CAS 7779-90-1); used elsewhere in dental cements, white pigment octylphenoxy polyethanol ethanol triphenol methane (scintillation surfactant) in undisclosed concentration (CAS 9036-19-5) |

hydrogen chloride

(hydrochloric acid) in undisclosed concentration; ClH (CAS

7647-01-0); used elsewhere in steel pickling, swimming pools,

rodenticide proprietary blend undisclosed concentration |

12-14% hydoxyacetic (glycolic)

acid C2H4O3 (CAS 79-14-1);

used elsewhere in household cleaners 3-5% sulfamic acid H3NO3S (CAS 5329-14-6); used elsewhere in swimming pool disinfecting and cleaning 3-5% citric acid C6H8O7 (CAS 77-92-9) 2-4% alkyl alcohol ethoxylate-acetate (CAS 68478-93-3) 2-4% proprietary detergent mixture |

35-40% proprietary

vinylidene-arcrylic copolymer 5-10% barium sulfate (sulfuric acid) BaO4S (CAS 7727-43-7); used elsewhere in filler and whitener 1-3% 2-Butoxy ethanol (CAS 111-76-2); colorless liquid used elsewhere in cleaners and as solvent 1-3% proprietary organic acid |

45-50% acetone C3H6O

(CAS 67-94-1); used elsewhere in solvent 40-45% dimethyl ether C2H6O (CAS 115-10-6) ;used elsewhere in solvent, aerosol propellant 5-10% 2-butoxy ethanol (CAS 111-76-2) |

proprietary mixture undisclosed

concentration mineral acids |

Active Ingredients |

| Characteristics | pH = 3.7 to 3.9 specific gravity = 1.11 |

pH = no data specific gravity = no data |

pH = 2.5 - 2.8 specific gravity = 1.19 |

pH = no data specific gravity 1.13 |

pH = 1.5-2.5 specific gravity = 1.2 |

pH = no data specific gravity = no data |

pH = 1.0 - 2.0 specific gravity = 1.105 |

pH = no data specific gravity = no data |

pH = no data specific gravity = 1.115 |

pH 0.= 1 - 1.0 specific gravity = 1.060 |

pH = 1.45 - 1.6 specific gravity = 1.05 - 1.07 |

pH = 1.95 specific gravity = 1.202 |

pH = no data specific gravity = no data |

pH = no data specific gravity = 1.08 |

Characteristics | |

| Other Information | Manufacturer's Description: Surface of rust is left black | Available in crystalline

concentrate which costs less. Full immersion required unless cream form is used. Manufacturer's Description: Biodegradable; Contains no hazardous or highly corrosive mineral acids or toxic volatile acids, such as muriatic acid or phosphoric acid. Will not harm plastic, paint, glass, aluminum, copper, brass, nickel, chrome, ceramics, or glazed tile. Will, however, attack zinc, lead and tin alloys. Heat will speed process. |

full immersion required Manufacturer's Description: bio-degradable, non-toxic |

Manufacturer's Description: Converts rust through an exclusive chemical process to an insoluble black coating |

Manufacturer's Description: MP-7 is designed to dissolve rusts and oxides from metal surfaces. Chemically, it reverses the rusting reaction and cleans away all oxidation from the metal. Also, minute crystals are formed that become integral with the surface molecules of the base metal, inhibiting further oxidation. These deposits are completely inert and do not change the tolerances or the conductivity of the metal. After the rust is dissolved and MP-7 has dried, the surface is ready for the next step, whether it be painting or welding | Manufacturer's Description: Neutralizes rust. Gently etches metal while simultaneously leaving a zinc phosphate film to promote chemical bonding. | Available from TAIOWA 1704 E. Main St. Endicott NY 13760 phone: 607-785-6170 fax: 67-785-0520 email: taioa@spectra.net web: http://www/spectra.net/~taiowa Manufacturer's Description: a serious, industrial-strength chemical, which, because it is chemically buffered, is safe, fumeless, and harmless to your kin when used according to all directions and your common sense |

Recommended by Thom

Fitzpatrick Manufacturer's Description: As seen on TV |

Per John S. Henry johnshenry@sprintmail.com, liquid better than aerosol. Converts rust to black, inert substance which includes magnetite (Fe3O4) | Manufacturer's Description: Completely passivates the rust, chemically preventing it from participating in further corrosion. Each molecule of RUST-X can attract and incorporate several iron atoms, and each single iron atom can be linked to three different molecules within RUST-X. The result is that RUST-X envelopes the rust at the molecular level, developing into a neutral layer which exists between the steel surface and the atmosphere. The neutral layer prevents the migration of ions so that no chemical reaction can occur. Dispersible in water | Comments | |||||

| Product Name | electrolysis | Ecotec | Simple Solutions Rust Remover | Rust-Mort | MP-7 | Naval Jelly | Dupont 5717S | Mirachem 250 | Dupont 5718S | Metal-Ready | Envirosolve 1000 | CLR - Calcium Lime & Rust Remover | Extend | One-Step | Rust-X | Product Name |

| Results after short treatment and no brushing- photographed dry |  |

|

|

no picture

|

|

|

|

|

|

|

|

|

|

|

|

Results after short treatment and no brushing- photographed dry |

| Results after short treatment and no brushing - photographed wet |  |

|

no picture |

|

|

|

|

|

|

|

|

|

|

|

Results after short treatment and no brushing - photographed wet | |

| Results after long treatment and brushing - photographed dry |  |

|

|

no picture |  |

|

|

|

|

|

|

|

long duration treatment not applicable to conversion treatments |

long duration treatment not applicable to conversion treatments |

long duration treatment not applicable to conversion treatments |

Results after long treatment and brushing - photographed dry |

| Product Name | electrolysis | Ecotec | Simple Solutions Rust Remover | Rust-Mort | MP-7 | Naval Jelly | Dupont 5717S | Mirachem 250 | Dupont 5718S | Metal-Ready | Envirosolve 1000 | CLR - Calcium Lime & Rust Remover | Extend | One-Step | Rust-X | Product Name |

| Untreated Comparison - right side was wire brushed before treatment; left side was left "raw" |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Untreated Comparison - right side was wire brushed before treatment; left side was left "raw" |

The following are my conclusions and recommendations for treating rust that I use in my shop (no powdercoating, plating, or galvanizing facilities). These are listed in order of my preference:

| 1 Sandblast - Sandblasting is

by far the best method for treating rusted metal. It leaves the metal very clean,

although some micro rust my be left embedded deep in the surface. It is also very

easy. There are some drawbacks including: |

2 Electrolysis

- Electrolysis seemed to work just as well if not better than other chemical treatments,

and since it is so inexpensive, it may be the way to go. There are drawbacks here

also:

|

| 3 Friendly Chemicals

- When I need to use acid treatments, I like to use the Ecotec. It is a little more

expensive, but it works very well and is friendly to use and dispose of. In my

experience, Simple Solutions is not a trustworthy business.

|

| 4 Plain Phosphoric

Acid Based treatments - These all seemed to work pretty well. Naval Jelly

is useful where a jell is needed to cling to surfaces. Dupont 5717S comes in a

concentrated solution which should be diluted according to the manufacturer's directions.

I have used 5717S undiluted on though rust and it works very well, but it is nasty

to work with.

|

| 5 Phosphoric Acid

with Zinc - I would not use these as a rust treatment alone, since the

concentration of phosphoric acid is less than the plain phosphoric acid based treatments.

However, when used after treatment with the plain phosphoric acid based chemicals,

the zinc in these treatments may do some good. The scary part is that directions

indicate that the parts be cleaned with water after treatment. Cleaning raw steel

with water is not something that thrills me. The steel seems to oxidize immediately,

but this might just be the zinc that is oxidizing.

|

| 6 Other Acids -

CLR seems to work okay and is pretty inexpensive. I prefer the phosphoric

acid since it leaves the iron phosphate residue. I found no benefit for the

Envirosolve 1000 (expensive and no residue).

|

| 7 Conversion Coatings

- I do not "believe" in these treatments, and you must have faith to believe the

manufacturer's claims. They are supposed to "convert" the rust, but after

using them, I have scrapped them off and found rust still there underneath. If you

think about it, these products dry in a matter of minutes. How can this provide

enough time for the product to penetrate into and convert the rust?

|

Nothing on this page should be construed as following scientific method. These comparisons were done pretty much off the cuff in my shop. Any conclusions or recommendations are purely my subjective opinion.

This page was found at the site http://EcologicArchitecture.com/SoloHobbit/ and was last updated on May 24, 2000 (and slightly revised since)by me,SoloHobbit@EcologicArchitecture.com